รายละเอียดสินค้า

วีดีโอ

รายละเอียดสินค้า

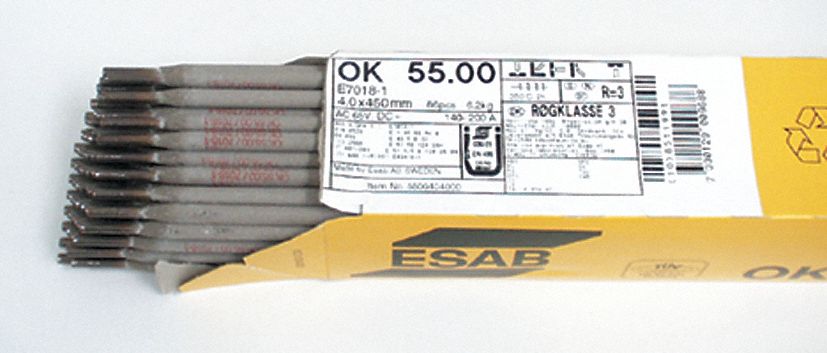

OK 55.00

| Classifications: | SFA/AWS A5.1 : E7018-1H4 R CSA W48 : E4918-1-H4 EN ISO 2560-A : E 46 5 B 32 H5 |

| Approvals: | ABS : 3Y H5 BV : 3Y H5 CE : EN 13479 CWB : E4918-1-H4 DB : 10.039.03 DNV-GL : 3Y H5 LR : 3Y H5 RS : 3Y H5 VdTÜV : 00632 NAKS/HAKC : *5.0mm |

Approvals are based on factory location. Please contact ESAB for more information.

| Welding Current: | AC, DC+ |

| Diffusible Hydrogen: | < 4.0 ml/100g (< 3 for most of the batches) |

| Alloy Type: | Carbon Manganese |

| Coating Type: | Basic covering |

Typical Tensile Properties

| Condition | Yield Strength | Tensile Strength | Elongation |

| ISO | |||

| As welded | 500 MPa | 590 MPa | 28 % |

Typical Charpy V-Notch Properties

| Condition | Testing Temperature | Impact Value |

| ISO | ||

| As welded | -50 °C | 110 J |

| As welded | -45 °C | 105 J |

Typical Weld Metal Analysis %

| C | Mn | Si |

| 0.06 | 1.5 | 0.5 |

Deposition Data

| Diameter | Current | Voltage | kg weld metal/ kg electrodes |

Number of electrodes/kg weld metal |

Fusion time per electrode at 90% I max |

Deposition rate 90% I max |

| 2.5 x 350 mm | 80-100 A | 23 V | 0.64 | 66 | 64 s | 0.9 kg/h |

| 3.2 x 350 mm | 110-140 A | 23 V | 0.62 | 41 | 72 s | 1.2 kg/h |

| 3.2 x 450 mm | 110-140 A | 24 V | 0.69 | 30 | 88 s | 1.4 kg/h |

| 4.0 x 350 mm | 140-200 A | 23.2 V | 0.62 | 28 | 72.5 s | 1.77 kg/h |

| 4.0 x 450 mm | 140-200A | 24 V | 0.71 | 19 | 94 s | 2.0 kg/h |

| 5.0 x 450 mm | 200-270 A | 24 V | 0.72 | 13 | 94 s | 3.0 kg/h |

| 6.0 x 450 mm | 215-360 A | 25 V | 0.71 | 9 | 98 s | 4.0 kg/h |

วีดีโอ